WhatsApp)

WhatsApp)

both. One example is using a stirred ball mill such as an Attritor to perform the first stage of grinding and then achieving the final polishing grind with a

AFT Fasteners, Services, Custom Solutions. Our projects vary in size from professionally engineered prototypes, common shortrun projects, and mass production .

Tribology glossary index ... Listen to pronunciation

Steelmakingandbilletproduction Ovako has four steel works, three of which have a scrap melting electric arc process and one blast furnace – oxygen converter process.

3 PRODUCT PRESENTATION Increasing capacity without signifi cantly increasing operating costs—that''s the goal of mining and aggregate producers through

Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granules. It consists of two horizon...

global webcast auction big rock energy services late model pci industries mobile high pressure nitrogen generating unit mack, ihc freightliner flush by/ rod rig ...

Jeffrey A. Klinger, Vice President and Cofounder of Custom Processing Services, Inc. talks to AZoM about coarse grinding techniques used to reduce particle size.

b) List of Primary Lending Institutions (PLI) (Scheduled Commercial Banks, State Financial Corporation (SFC) the NSIC Ltd, Cooperative Banks, Regional Rural Banks ...

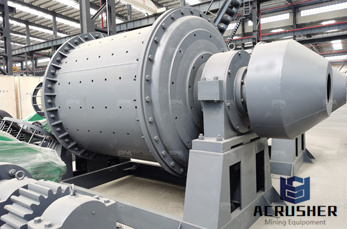

Size Reduction. Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a ...

4 Figure 3: IsaMill Grinding Mechanism Chamber occur between disks due to variation in As a result of having 8 chambers in series, short circuiting of mill feed to ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Pharmaceutical particle technologies: An approach to improve drug solubility, dissolution and bioavailability

Paul O Abbe Equipment Company is a manufacturer New Ceramic Lined Ball Mills and Milling Equipment. Call or request a quote to get started.

The list of provisional Machinery suppliers is given below. The borrowers should excercise atmost care in selecting the machinery supplier after carefull examination ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

particle size distribution effects that should be considered when performing flotation geometallurgical testing % %

SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range.

Raw Materials Dictionary / Ceramic Pottery Glaze making, Clay Ingredients

Air Products'' PolarFit ® cryogenic grinding solutions can help you grind more effectively and efficiently, particularly for heat sensitive or toughtomill materials.

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

6 Figure 5: I Further, the ratio between mill airflow rate and separator speed influences the particle size distribution. A lower air flow rate will lead to a lower ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

WhatsApp)

WhatsApp)