WhatsApp)

WhatsApp)

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process .

Shanghai Lipu Heavy Industry Co,Ltd Ball . Mineral Construction Equipment with over 15 Years Experience We supply ball mill, crusher, flotation machine, magnetic ...

Advanced Controller for Grinding Mills: Results from a Ball Mill Circuit in a Copper Concentrator Anoop Mathur, Sujit Gaikwad, Honeywell Technology Center

Autogenous mills, semiautogenous mills and . mills and ball mills for wet grinding A company of Polysius provide process engineering design layout, Ball mill for ...

Ball Mill Inspection ... On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working ... Ball Mill Grinding.

The technological production process of manganese metal powder. Ball mill is the oldest grinding miller that is widely used in the preparation of chemical materials ...

We are a Professional Copper grinding machine manufacturer,Our Copper grinding machine has been exported 167 countries,Click here to get price !

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

MPES provides engineering services in mineral processing. Particularly, for grinding and flotation. MPES experts of grinding (HPGR, SAG/AG, Ball Mill grinding) and ...

Video embedded· Common types of grinding mills include Ball Mills and ... the use of the product or the subsequent process. ... Grinding Mill Feed Chutes. Grinding mills for .

1. Introduction. Ball mill grinding is a fundamental operation process, and in many respects the most important unit operation in a mineral processing plant.

In this page, you can find crusher,jaw crusher,Impact crusher,CS series cone crusher,vertical roller mill,ball mill,We company is a .

Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, ...

cement plant equipments manufacturer and . Cement Plant Equipments: We known for quality equipments manufactures and supplier of clinker grinding units, rotary kilns ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

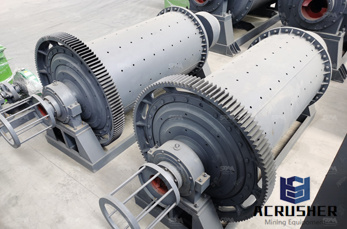

Ball mill, an energysaving grinding device, is widely used in mineral processing, building materials and chemical industries. Ball Mill grinds material by rotating a ...

SAG is an acronym for SemiAutogenous Grinding. SAG mills are autogenous mills but use grinding balls like a ball mill. A SAG mill is usually a primary or first stage ...

Ball mill grinding process technology description, Ball mill grinding operation is to continue the process of crushing the ore, is the preparation work of sorting ...

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

Intelligent optimal control system for ball mill grinding process. Operation aim of ball mill grinding process is to control grinding particle size and circulation ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while ...

CEMENT GRINDING OPTIMISATION ... the grinding process is more of an ... There are efficiency factors for dry grinding, open circuit ball milling, mill diameter,

WhatsApp)

WhatsApp)