WhatsApp)

WhatsApp)

cement tube mill charging media calculation ... are working every day with a cement ball mill, ... grind wood with varnish; cement grinding mill motors 100 hp ... ball mill grinding media percentage grind media distribution calculation for ...

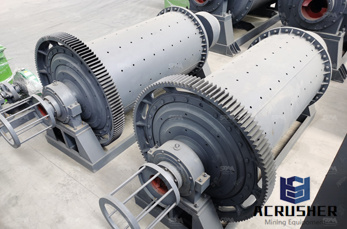

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

2017/08/09· The ball mills are often applied in mineral processing, they are an important part of the cement industry. A key factor, which influences the milling process, is the granular flow of grinding media. The flow determines ...

Table of ContentsTypes of Grinding Mill ManufacturedROD MILLSPEBBLE MILLSSelecting Wet or Dry Grinding MillHow much grinding power is neededSAG Mill vs Ball MillMill speed and grinding charge volumeGrinding ...

Simulation of a ball mill operating with a low ball charge level and a balanced ball size distribution. Simulação de moinho de bolas operado com baixo... Read more how to charge media in ball mill Read more ...

performance. Ball mill performance is affected by the ball size distribution. In the following paragraphs ''good'' and ''bad'' case studies will be presented as a part of previous work done to identify how a ball size configuration may affect ...

Effects of grinding media shapes on load behaviour and mill power in a dry ball mill Lameck *, Kiangi, Moys School of Chemical and Metallurgical Engineering, University of the Witwatersrand, Private Bag 3 ...

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The ...

Ball mill in AUTOCAD DRAWING BiblioCAD section in terms of the numbers of ball and rod mills used previously. ... media and the ore to be drawn upwards with the mill liners and tumble, causing... Images forball mill section ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand ...

REGARDING % OF GRINDING MEDIA IN THE MILL,, 1125 125 USED IN FINDING THE PERCENTAGE OF GRINDING MEDIA INSIDE THE MILL I E,h/d*, MILL CHARGE VOLUME VOLUME LOADING (%) =113 (126 ...

effect of operational variables on ball milling Poli Monografias UFRJ actual contribution of the fine ore both on the charge movement and on the ... Figure 3 6: Examples of movement of the media inside a ball mill simulated using ..

Effects of slurry filling and mill speed on the net power draw of a Nov 11, 2014 The net power draw and media charge position were measured. volume on net power draw especially for an underfilled media The size of lifters and ...

effects of grinding media shapes on ball mill performance Ball size distribution inside an industrial mill was analysed in terms of shapes, Considering that worn balls in an industrial mill charge constitute about 15 to 40 » Learn More ...

meghna cement mills ltd pattern distribution system charge media distribution inside ball mill distribution of iron ore in the world distribution of limestone in india About CNcrusher Shanghai CNcrusher Mining and Construction ...

Grind Media Distribution Calculation For Ball Mills SAG Mill Testing Test Procedures to Characterize Ore ... PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY ... size distribution. MODIFIED BOND BALL ...

The number of balls, having the determined diameter in a mill, depends on the ball size distribution in the charge. Let us suppose that the ball size distribution in the charge can also be depicted by GaudinSchumann''s equation: c ...

The choice of media charge composition that optimizes ball milling circuits has had significant financial implications. This problem has been industrially addressed using a trialanderror approach coupled with experience. Mill 2. ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

grinding media charging ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different ...

THE DISTRIBUTION OF ENERGY IN GRINDING CHARGE OF BALL MILLS PRICHICI Mariana, INDRIE Liliana, GHERGHEL Sabina, ALBU Adina University of Oradea, Faculty of Management and Technological Engineering,

International Journal of Mineral Processing, 40 ( 1994 ) 171186 Elsevier Science, Amsterdam 171 Simulation of charge motion in ball mills. Part 1: experimental verifications Mishra and Raj K. Rajamani ...

Cement mill WikipediaA cement mill is the equipment used to grind the Charge Media Distribution Inside Ball Mill hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ...

media segregation in ball mill – SAMAC Mining predicting charge motion, power draw, segregation and wear in ball . Particle j~ows in a 5 m diameter ball mill ... Ball mil design calculation? Yoo Answers I need to design a l end ...

WhatsApp)

WhatsApp)