WhatsApp)

WhatsApp)

Comparison of Economic and Technical Features of Fluid Bed and ... Fluid Bed (CFB) and Spray Dryer ... There are 705 coalfired EGU boilers currently in service at an ...

coal fluid bed dryer Coal Dryers | Carrier Vibrating . Carrier vibrating fluid bed thermal dryers are typically used for coals with a larger size ...

Coal Creek Prototype Fluidized Bed Coal Dryer: Performance Improvement, Emissions Reduction, and Operating Experience Charles Bullinger and Mark Ness

TTPL is one of the best coal dryer ... The coal dryer works on the principle of agitated fluid bed coal drying. The coal dryer removes the moisture from ...

FMC Technologies'' FluidBed Coal Dryers are capable of processing 100 800 tons per hour of coal, and evaporating up to 50 tons per hour of water. The coal

ThermaFlite, a leading manufacturer and supplier of screw dryers, comes up with highly advanced Coal Dryer systems for drying coal fines efficiently. Call us at (707 ...

Fritz Winkler created the first fluidised bed in 1922 for coal ... The annular fluidized bed is a new type of ... These applications can range from dryers ...

Fluid Bed Dryer For Coal, Wholesale Various High Quality Fluid Bed Dryer For Coal Products from Global Fluid Bed Dryer For Coal Suppliers and Fluid Bed Dryer For Coal ...

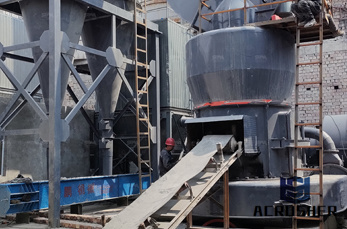

Manufacture of Vibratory Fluid Bed Coal Dryer. Kilburn Engineering Ltd. is a leading design and manufacture of Vibratory Fluid Bed Coal Dryer in collaboration with ...

Schwing Bioset''s Fluid Bed Technology Group offers complete systems for processing of powders, granulate, pellets crystalline solids

Schwing Bioset offers coal drying technologies for a variety of coals. Extremely high thermal efficiencies are obtainable with the use of a fluidized bed in the process.

Product Profile. Carman Vibrating Fluid Bed Processors are the perfect way to heat, cool, dry, or moisturize your bulk solid material. By passing controlled process ...

Introduction of Fluidized bed furnace Combustion mode is coal fired after crushing into 10mm following particles,through the coal feeding machine put into fluidized ...

Fluidizedbed drying with internal waste heat utilization (WTA)

A fluidized bed dryer arrangement for drying of coal at elevated pressure comprising a container (1) with at least one arranged in the upper region of the container ...

IV. D ESIGN OF FLUIDIZED BED DRYER A. Theoretical design of Fluidised bed Dryer A fluidised bed dryer is designed for preheating of kiln feed (coal) using waste gas ...

Like a Fluidized Bed Dryer, ... Material to be cooled is fed from one end of the fluid bed and it moves along the bed in a fluid state to the ... India. Ph : +91 ...

Operation: Fluid bed drying uses a heated gas to lift and maintain the feed in a fluidized state. Air is introduced into a wind box or plenum via a forced draft ...

FLUIDIZED BED COAL DRYING AT LOW TEMPERATURES by ... The experimental results on fluidized bed coal drying ... The coal residence time in the dryer .

Basic model. When the packed bed has a fluid passed over it, the pressure drop of the fluid is approximately proportional to the fluid''s superficial velocity.

Dryers for the Demanding Requirements of Thermal Coal Drying Vibrating Fluid Bed Dryers Over the past 50 years, ...

Coal Dryer; Coal Dryer. KILBURN ... The hot gas is introduced in the Fluid Bed Dryer at the bottom of vibrating bed ... Vibrating Fluid Bed Dryer (VFBD) – VFBD coal ...

A STUDY OF THE DESIGN OF FLUIDIZED BED REACTORS FOR BIOMASS GAS IFICATION UC]L I I Ajmal LatifMEng. A Thesis Submitted for the .

For fluidized bed dryer for coal drying, they have been in The maximum inlet temperature for conventional fluidized bed dryer/ calciner is around 650 C due to.

WhatsApp)

WhatsApp)