WhatsApp)

WhatsApp)

Unicast Grinding Mill Parts combined provide a complete system for optimized wear life of grinding mill parts with cost savings and minimum down times.

Piling Accessories Coatings Coal Tar Epoxy Product Description High solids, high build polyamide cured coal tar epoxy coating.

Fulltext (PDF) available on request for: Coal mills. Behaviour of wear resistant parts. List of factors affecting abrasion phenomena for different types of mills.

SURFACE COAL MINING MANAGEMENT. Paul Westcott. The geological characteristics of surface coal mining which distinguish it from other surface mining are the nature of ...

Magotteaux. Process optimisation solutions for high abrasion extracting industries. Starting with a cross section insight of your valuechain, combining expert advice ...

Limestone and Lime Limestone is an odorless white, grayishwhite or tan material that ranges from sized stone to a granular powder. It is often described as the most ...

ore abrasion index for coal. ore abrasion index for coal. JORC Coal Guidelines Mineral Resources and Ore Reserves. ... Crushers, Pulverizers Mills ...

Multotec supplies the largest range of coal centrifuges, in basket diameters 800 to 1 650 mm. Vibrating and screen scroll centrifuges for coarse and fine coal.

Coal Analysis techniques are specific analytical methods designed to measure the particular physical and chemical properties of coals. These methods are used ...

Correspondence to: Dr. A. K. Bhakat, RDCIS, SAIL, Ranchi, India. Coal crusher hammers coke screen decks experience high impact and severe abrasion in coal mill ...

92% alumina ceramic in coal mill ... also act as abrasive with coal dust on mill internal surfaces * The abrasion can be greatly reduced by fixing Alumina ...

Abrasionresistant coal mill parts for bowl mills and components for pulverized coal transport systems.

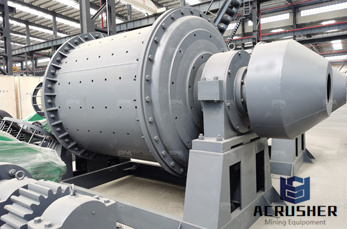

Grinding Mills,Wills'' Mineral Processing Technology ... Grinding is the last stage in the comminution process where particles are reduced in size by a combination of ...

More than 12,000+ ASTM standards are used worldwide to improve product quality, enhance safety and facilitate trade. You can purchase individual standards; a volume ...

Flat Back Elbows The pictures below show a sample liner that was manufactured in June of 2007 for installation in a flat back elbow. After 28 months of service, the ...

The Coal Mill Classifier Cone directs the pulverized coal out of ... DUROMARHAR was used and found to have both the abrasion resistance and ease of application ...

Advanced Coal Science Coal – How It Is Formed. Coal is made from Peat that has been compressed and then subjected to high temperature ( + 100° Celcius) for a few ...

Coal Processing Plants ... materials first enter jaw crusher to be crushed to best for material low in abrasion. raymond mill small investment, ...

Today''s energy dependence makes power generation one ... It is also an industry that faces constant amounts of highabrasion. Coal piping faces ... Coal Mill Inner ...

Hardfacing of wear surfaces for coal industry and ... and Alstom bowl mills. Our mill body wear ... abrasionresistant hardfacing can be applied to coal ...

KALCRET hard compound abrasion resistant linings are cement bonded for high wear resistance. KALCRETS is a sprayable lining for fast wear protection.

Material Testing Equipment Manufacturer and exporter of material testing equipment, material grinding equipment, laboratory pulveriser, labjaw crusher, roll ...

SGS can quantify the wear in your grinding circuit using the Bond Abrasion Test. This allows you to plan and predict liner replacement and maintenance.

Discover all the means used to grind your material in a mill on Magotteaux''s website. They are the only supplier offering a wide range of grinding media.

WhatsApp)

WhatsApp)