WhatsApp)

WhatsApp)

Pulverizer Coal Mill In Power Plant | Crusher Mills, Cone ..... supply coal mill maintenance, operation. ... pulverized fuel coal mill control Improved coal grinding ...

pulverizer mill parts | Solution for Mining Quarry. what is the operation of the mill and pulverizer. Optimum Operation and Maintenance of EL Pulverizers EL ...

Pulverizer Capacity is not simply "tons throughput per hour!" While throughput is large factor in pulverizer capacity, many other aspects can dramatically ...

ai01es (ai0104es) Instrumentacion de Control lesson; el01es (el0102es) Diagramas Esquematicos lesson; el02es (el0201es) Codigos y Normas de Seguridad lesson

Performance Driven Maintenance of Coal ... Pulverizer performance testing provides insight to operation ... By conducting periodic Isokinetic coal sampling ...

Principal. Coal based thermal power plant works on the principal of Modified Rankine Cycle.

New Technology Coal Pulverizer Manufacturer,Coal Pulverizing Mill, Find Complete Details about New Technology Coal Pulverizer Manufacturer,Coal Pulverizing Mill,Coal ...

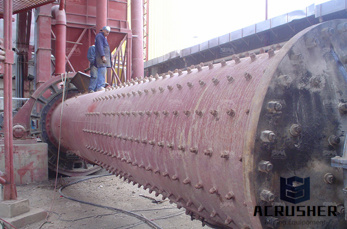

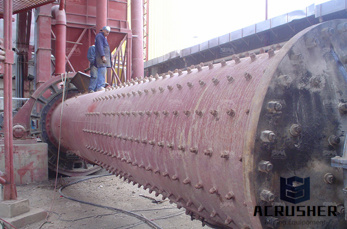

Ball tube mill. Ball tube mills are either pressurized or suction type. In the pressurized type, the hot primary air is used for drying the coal and to transport the ...

Advantages of coal based thermal Power Plant. They can respond to rapidly changing loads without difficulty; A portion of the steam generated can be used as a process ...

mills is its double end operation, each end catering to one elevation of a boiler. Coal ... Coal mill pulverizer in thermal power plants ...

Hammermill. American Pulverizer Hammermills offer flexibility, uniform reduction, and economical operation. Hammers are reversible—with two or more crushing ...

coal mill operation in pulverized fuel. Pulverized coal injection in a blast furnace, ... For example, a pulverizer mill is used to pulverize coal for ...

Manufactures wide range of size reduction equipment for handling wet or dry and light or heavy materials. Includes hammermills, lumpbreakers, wood grinders, and jaw ...

Home / Coal / CoalFired Power Plant Heat Rate Improvement Options, Part 1; CoalFired Power Plant Heat Rate Improvement Options, Part 1. 11/01/2014 | Sam Korellis

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

ACM means Air Classifying Mill, which is able to adjust the particle size through air classification when grinding. ACM Pulverizer

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Selection of the type of pulverizer depends on the grindability of the coal, ... Types of Coal Pulverizers in ... is an important function in the operation of a ...

Pulverizer Wikipedia, the free encyclopedia. In addition to raising the coal temperature inside the mill for drying and better grinding the same air works carrying ...

Copyright © 2009 MISTRAS Group Inc. All Rights Reserved. #18009 Specifications subject to change without notice. Coal Flow Monitoring System

Combustion Engineering 783RP BowlMill Coal coal pulverizer designs are Vertical Roller. ... These have impacted the coal mill and power plant operation safety and ...

AgroMachines And Allied Equipments We offer a wide range of oil expellers, chaff cutters and allied equipment that find extensive usage in the agriculture industry.

RSEP181 Rajco Laboratory Pulverizer is a disc type grinder, designed for grinding material to produce a fine mesh sample in one operation.

Commercial Food and Cheese Chopping and Cutting Equipment. Schier Company Inc. has a wide variety of cutters available including grinders, shredders, flakers and ...

WhatsApp)

WhatsApp)