WhatsApp)

WhatsApp)

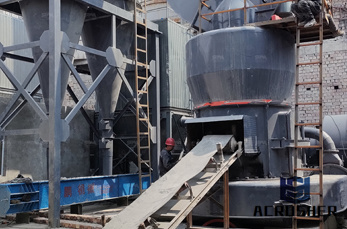

1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals, Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and ...

Hammer mill design calculation YouTube 11 Dec 2016, Design and Analysis of Rotor Shaft Assembly of Hammer Mill Crusher the Design, calculation Crusher South Africa hammer mill design calculations pdf, SAMAC design ...

The Hammer Mills HM 341 and HM 671 in a robust industrial design are used for crushing soft to hard, tough or damp materials by the principle of physical impact. ... This hammer mill is used for crushing rock salt in underground ...

Since 1925, Prater has utilized the most advanced technology and innovative solutions to create stateoftheart Hammer Mill and size reduction products that are used around the world. Our exclusive GSeries, Full Screen, Hammer ...

めまれている· Hammer mill wood grinder is suitable for processing the materials after shredding(The material size: Max length≤3cm;Max width≤3 cm; Max thickness≤2 cm), this machine has some special design for fiber material, wet and oil ...

The common wood hammer mill is ideal for wood material grinding and plays important role in wood pellet plant. With heavyduty rotor design, this sawdust machine works efficient and makes uniform sawdust.

Introduction hammer mill is used to crushing the grains like corn, bean, wheat into powders for animal poultry feed. hammer mill can also crushing wheat straw, rice straw and so on. kind of feed hammer mill ...

3 High speed low sensitivity HAMMER MILL Hammer mills are used for primary and secondary crushing of diff erent types of material in almost all industrial sectors. FEED MATERIAL Hard coal and lignite in coal ...

2. A hammer mill as claimed in claim 1 wherein the screen plates, side plates and screen frame are incorporated around a radial plane of the rotor of the horizontal hammer mill and a maximum width from a left side of the screen ...

Wide Chamber Feed Hammer Mill Introduction As a universal type feed grinding machine, wide chamber feed hammer mill is often used for fine grinding. ... Model Power Spindle Speed Grinding Room Width Hammer Qty General ...

Grain Hammer Mill is suitable for coarsegrinding and finegrinding of various granular grain materials, such as corn, sorghum, rice, wheat, soybean meal, cottonseed meal, rapeseed meal. The fine grinding can realize 60mesh.

• Unique design utilizes of the screen area • Uniform granular grind • Electronically balanced, reversible rotors • Efficient use of power ...

AU 8(3): 124130 (Jan. 2005) Development and Testing of a Hammer Mill A. Nasir Department of Mechanical Engineering, Federal University of Technology Minna, Niger State, Nigeria Abstract The hammer mill was designed ...

Hammer Mills Hammer Mills Types Hammer mill 2000х2590х750 Hammer mills are designed for getting fine grinded products in the process of simultaneous... Hammer tangential mill 1300х1300 Hammer tangential mills are designed ...

Design Of Hammer Of Hammer Mills For Optimum Performance In Cement Plants Design of hammer mills for optimum performance | QUT ePrints 15 Jan 2009 Kosse, Joseph (2001) Design of hammer mills for optimum performance ...

Design and Development of a Petrolpowered Hammer mill for rural Nigerian Farmers. Adekomaya,, and , Department of Mechanical Engineering, Olabisi Onabanjo University, Nigeria *Corresponding Author on the ...

The hammer mill is suitable for mill wood chips,tree branchs with diameter less than 50mm, wood sawdust, peanut shell, corn stalk, etc. after milling, the output size is 35mmfor pellet mill use. Hammer mill is popular with biomass ...

power calculation for ball mills ball mill power calculation pdf in India ... mills 229 In order to design ... volume calculation for ball mill ... Calculation ... Conveyor Motor Power Calculation This is vidyaprakash from ...

TELKOMNIKA IJEE eISSN: X Development on a Hammer Mill with Separate Sieving Device (ChuanzhongXuan) 1383 When material being ground is fed into the grinding chamber from the inlet, it is ground by the high ...

There are three basic areas of hammermill maintenance: 1) Routine replacement items such as screen, hammers, and pins 2) Regular long term maintenance items such as flow directors, regrind chamber, and bearings Tip Speed ...

4 Compact controller. Efficient and reliable. Control The DFCO hammer mill controller controls the entire grinding process. In addition to the main functions such as starting and stopping all motors, it also monitors all the necessary ...

Working width: 300 – 2000 mm Hammer Mill Type HM 450/600 Advantages flexibility in their application range heavy duty design reduced space requirement due to compact design energysaving size reduction Author 2/5 ...

Wood Pallmann The length of the chips depends on the drawin feed, the number of knives, ... The Impact Hammer Mill, type PHPH was especially designed for the .... This cutting action results in rectangular flakes with smooth ...

Home > Grinding Equipment > design of rectangular blades for a hammer mill Products Crushing Equipment PE Series Jaw Crusher PEW Series Jaw Crusher HCS Series Cone Crusher HP Series Cone Crusher S Series Cone ...

WhatsApp)

WhatsApp)