WhatsApp)

WhatsApp)

For Life Science Professionals Process Verification vs. Process Validation: What You Need to Know by Andrew Snow, Momentum Solutions, LLC and Walt Murray ...

electro chemical grinding process ppt Coal Surface Mining. electro chemical grinding process ppt Description : Lecture 6 Electrochemical grinding (ECG) is an ...

Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte ...

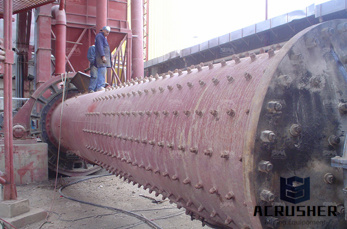

Electro Chemical Grinding (ECG) Electrochemical grinding combines both electrolytic action (90%) and physical grinding (10%) to provide precision, burrfree and ...

Electroless Nickel Plating is used to deposit nickel without the use of an electric current. Since gaining commercial use in the 1950s, electroless nickel plating has ...

Surfynol is used as an antiing wetting agent or antiing agent in mainly waterborne materials such as paints and inks.

The following are manufacturing and related tools, data, articals, as well as Design for Manufacturability DFM resources.

We offer engineered and performance coatings to increase the life and performance of critical equipment processes. Primary Markets: Aerospace, FAA Repair, Defense ...

Electrochemical grinding Wikipedia, the free encyclopedia Process[edit]. The wheels are metal disks embedded with abrasive particles. Copper, brass, and nickel ...

ElectroChemical Grinding. Electrochemical grinding (ECG) is a variant process of the basic ECM. It is a. burr free and stress free material removal process, wherein material removal of. the electrically conductive material takes place through mechanical (grinding) process and electrochemical process.

PE Process Chemical Engineering: Reference Course Title Duration Add for me; PE001: Industrial Drying, Principles, Selection and Design: 5: Add to upcoming calendar

CONTROL VALVE HANDBOOK Third Edition FISHER CONTROLS INTERNATIONAL, INC Marshalltown, Iowa 50158 Cernay 68700 France Sao Paulo 05424 Brazil Singapore 128461

Abstract— This paper reports the development of the mathematical modeling of an abrasive electrochemical grinding (AECG) process. In AECG a metalbonded ...

Searchable Engineering Catalogs on the Net. Hundreds of thousands of products from hundreds of suppliers of sensors, actuators, and more, all with searchable specs.

Electropolishing for Deburring Metals. The electropolishing process is wellsuited for deburring. During the process, the transfer of metal ions occurs most rapidly ...

What is Electrochemical Grinding? ... high current electrical energy supplied by a properly designed DC power supply is central to the Electrochemical Grinding process.

22. Expected Salary (Per Month): 23. Work Location Preferred: Distt. State: India: Overseas: 24.(I) Preferred Job Type:

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

Electrochemical Grinding (ECG) Process Overview. Electrochemical Grinding, or ECG, is a variation of ECM (Electrochemical Machining) that combines electrolytic activity with the physical removal of material by means of charged grinding wheels.

calculate the theoretical deposit weight of any metal that we are plating based on its atomic weight and the number of electrons involved in the electro

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

ExxonMobil Chemical''s LLDPE resins provide very good moldability for a wide range of rotational and injection molding applications, offering good flexibility and ...

EDM Machining (Electrical Discharge Machining) makes it possible to work with metals for which traditional machining techniques do not work. Learn about Wire EDM ...

Product Catalog of Epoxy Epoxy Resins, Hardeners and, Other Construction Resins. Here is a list of the current Our Products. In addition to the products below, we ...

WhatsApp)

WhatsApp)