WhatsApp)

WhatsApp)

A cement mill (or finish mill in ... Heat generated in the grinding process causes gypsum ... These have been used for many years for the less exacting rawmilling ...

Raw Material Vertical Roller Mill CHAENG. These units can process both raw and mill which is the biggest homemade raw material vertical roller mill, into the center ...

process – regardless of variations in ... The grinding table of the ATOX raw mill has a flat, horizontal grinding track encircled by an adjustable dam ring

FCB has just developed a new mill, HOROMILL ®, for grinding cement, raw meal and minerals. This new grinding process is designed for finish grinding and also for ...

raw mill grinding process. raw mill grinding process is one of the products of our company main products sold,it is not only good stability, high reliability, ...

Cement Manufacturing Process Raw Materials The hydraulic property of cement originates from its cement minerals ( calciumsilicates). The major co...

vertical raw mill process control vertical raw mill process control,Ball grinding mill, roller grinding mill for slag, coal Alternative raw materials (ARM) like ...

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

raw mill grinding process Crusher Price. Raw material grinding manufacturing industry is the hammer mill and the operation of such machines is illustrated in Figure 2.

Advanced process control for the cement industry ... A raw mill stoppage is another ... Ball mill application Ball mill grinding is a highly

A mediumsized dry process roller mill. ... The history of the development of the technology of raw material grinding defines the early history of cement technology.

cement ball mill ventilation process . ... In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, ...

cement plant concepts is to adapt the raw mill production rate to the needs of the ... The tradition process of tube mill grinding system is high energy ...

Through the understanding and analysis of raw material grinding, how to optimize the process parameters to ensure quality, improve production, reduce energy ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... grinding of raw materials and ... In a cement vertical roller mill grinding is performed in .

An additional benefit of separate grinding of raw material components ... Parent Process: Raw ... mill by ball mill (40 t/h) and high pressure grinding ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION ... Experience has shown that the potential for optimisation is greatest in the cement grinding process .

Modeling for the ball mill grinding process is still an imperative but difficult problem for the optimal control ... discripion of all parts vertical raw mill with ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are ... vertical mill grinding ...

Search cement grinding mill process example to find your need. Mining and ... Mill autogenous mill grinding Iron ore grinding mill such Raw mill is ...

Mill (grinding) Attrition Mill; A ... ball mills in a grinding process. Like ball mills, grinding ... or pulverizing of grain and other raw materials using cylinders ...

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw ... cement grinding ... grinding balls from leaving the mill.

Cement Mill/Final Grinding Process The ... The mix is fed to the raw mill for drying, grinding. SPEX SamplePrep Equipment Accessories 6970EFM.

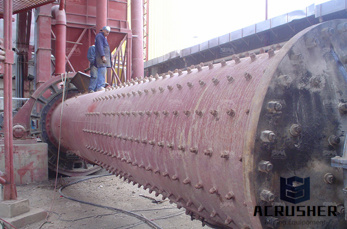

Product information: Raw material mill, also called raw meal mill, is important grinding equipment in cement production process. After being crushed, the raw meal ...

WhatsApp)

WhatsApp)