WhatsApp)

WhatsApp)

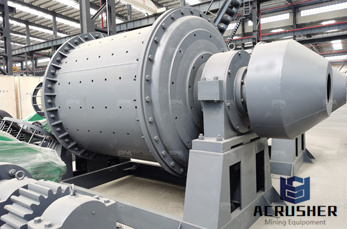

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, new ...

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., LTD. is one of largest professional manufacturers in China engaging in ... Lab Rapid Ball Mill; Lab Glove Box / Operation .

The machine running is smooth operation and reliable . Ball mill host, including cylinder body,which lined with wearresistant lining material, a load cylinder maintain ...

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

Safe Operation Ball Mill, Wholesale Various High Quality Safe Operation Ball Mill Products from Global Safe Operation Ball Mill Suppliers and Safe Operation Ball Mill ...

· Pulverizing the coal to a fine powder is often a critical function within the operation from the power plant. ... * This referred to as Tube mill or Ball mill These .

safe operating procedures for ball mill manufacturer in Shanghai, China. safe operating procedures for ball mill is manufactured from Shanghai Xuanshi,It is the main ...

Easy Operating Ball Mill, Wholesale Various High Quality Easy Operating Ball Mill Products from Global Easy Operating Ball Mill Suppliers and Easy Operating Ball Mill ...

Ball Mill Operation and Maintenance Source: clirik By Ammy Posted: . Ball mill has features of high operation rate, grinding effect, and we must follow ...

The ball mill is a classic piece of equipment for any lab. Our ball mills take care of general grinding tasks and provide reproducible results. Pulverizer;

Ball Mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size.

Ceramic ball mill . Cylinder speed:1436r/min Weight: Motor power: Ceramic ball mill is mainly used for mixing, grinding process. It can be used both ...

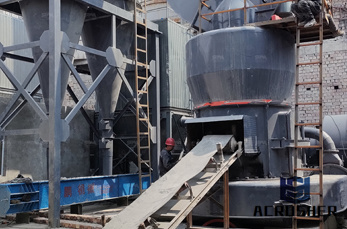

Ball mill operation is anything but simple. In ball mills using dry solids, the primary independent variables include mill speed, mill diameter, media size, residence ...

· RecrystallizedRocket. Loading ... Working principle of Ball Mill /ball cement milling machinery plant Group Duration: 3:46.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

operation of cement ball mill. operation of, pew series is born with innovative significance. It is newly designed and improved by our experts on basis of their ...

Ball mills account for the majority of all mills in cement plants and therefore the optimization of ... Optimizing the operation of the cement mill Publications.

Operation Notation of the Ball Mill kara liu . I drive method of the ball mill 1 before the operation we must check all parts according to the the contents itemized ...

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started.

Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

Operation Principle of Iron Ore Ball Mill Xinhai. The grinding operation of Iron ore ball mill has been very mature and its stable performance is why it has ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

WhatsApp)

WhatsApp)