WhatsApp)

WhatsApp)

• Standard Ashapurabentonite was used as binding agent Mix 02 • Corresponding to beneficiation layout design B • Standard Ashapurabentonite was used as binding agent Mix 03 • Corresponding to beneficiation layout design B ...

1. Introduction Iron ore pelletization plants in the United States used approximately 612,000 metric tons of bentonite as a binder to produce iron ore concentrate pellets in 2000 (Virta, 2001). It is a major cost item, with individual plants ...

Improvement of mechanical strength of iron ore pellets using raw and activated bentonites ... 25 shape. Bentonite is well dispersed and retains an even distribution of moisture throughout the wet pellet as it grows. During ...

Influence of the clays on the flotation of the pyritic gold ore was studied. • Bentonite depressed the pyrite recovery and modified the pulp rheology. • Kaolin did not affect the pyrite recovery and the pulp rheology. • The adverse effect of ...

MARKET STUDY OF BENTONITE PRODUCTS Prepared by: Ainsworth Jenkins Holdings Inc. and Master Mineral Resource Services Ltd. March, 1994 British Columbia Geological Survey Branch Ministry of Energy, Mines and ...

how to do bentonite wet process While activation with soda ash we make use of the method of wet activation,, how to do bentonite wet process,Ore Crusher,Grinding mill equipment,Crusher plant activating bentonite methods ...

Characteristic / Bentonites NorthBohemian bentonites are mined and processed since 1953. In 1969 based on geological survey and evaluation of raw material resources our factory in Obrnice near Most was put in operation ...

IRON ORE SUPPLY DEMAND SCENARIO IN INDIA (2000 2040) 2000 2010 2020 2040 Finished steel consumption 28 61 120 – 150 400 – 530 FSC per capita (kg) 30 50 90 – 110 260 – 340 Iron ore requirement 43 100 2002 ...

Finely comminuted, crude bentonite may be purified of accompanying quartz, muscovite, illite, feldspar, iron oxide and like impurities by pouring an aqueous slurry of the clay into a very dilute aqueous solution of a technical grade of ...

dry magnetic separation of iron ore for bentonite in africa Home dry magnetic separation of iron ore for bentonite in africa dry magnetic separation of iron ore for bentonite in africa Stone crusher in marashtra, Stone crusher in ...

PE series jaw crusher is usually used as primary crusher in quarry production lines, mineral ore cru. PFW Impact Crusher Base on the plentiful experience of producing and marketing of impact crusher, SBME RD institution . ...

Process for agglomerating ore concentrate utilizing clay and dispersions of polymer binders or dry polymer binders US A Samenvatting This invention is a method for agglomerating mineral ore concentrate comprising the ...

Application of Vietnam used ore hammer mill for bentonite: ore hammer mill (also called HM series coarse powder mill) is one kind of new high efficient grinding machine. This mill is mainly used for coarse powder and small size of ...

processing technology for bleaching bentonite Optimization of Bleaching Process AOCS Lipid Library The bleaching of edible oils and fats is a part of the refining process of crude oils ... One is calcium montmorillonite » » » ...

beneficiation process of bentonite_Crusher manufacturers beneficiation process of bentonite . more beneficiation process of bentonite online chat. hay is a ... used lmzg bentonite beneficiation process – ... ShangHai (bentonite ...

bentonite iron ore dewatering Iron Ore Processing for the Blast FurnaceCreating steel from lowgrade iron ore requires a long process of mining, crushing, separating, concentrating . dewatering. The product is called "filter . pellets.

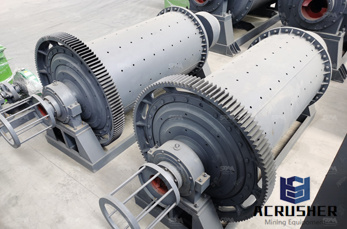

Crusher Machine For Sale The XSM is professional ore crushing machinery company,the company''s crushers machine for sale main stone crusher,grinding mill,sand making machine,mobile crusher and other ...

Gulin machine in bentonite production plant, complete bentonite raw material crushing plant for sale, bentonite raw material grinding plant, bentonite clinker processing plant manufacturer. Gulin provides crusehr and grinding mill in ...

2017/07/21· Microcrystalline silica impurities such as quartz and opalCT commonly associated in bentonite should be controlled and removed as far as possible when bentonite is used as biocompatible raw material because the ...

This invention is a method for agglomerating mineral ore concentrate comprising the commingling of mineral ore concentrate with a binding amount of water soluble polymers, preferably poly(acrylamides), and clay, preferably ...

Dry bentonite beneficiation scribd beneficiation process of bentonite. Bentonite beneficiation, Process, Machine, beneficiation process of iron ore hematite dry separation Bentonite Gypsum Granite Coal » Learn More Bentonite Ore ...

However, this modification was less significant in copper flotation in the presence of bentonite where pulp viscosity played a critical role. Keywords Cations Bentonite Viscosity Copper flotation Flotation rate 1. Introduction With the ...

Unique challenges of clay binders in a pelletised chromite prereduction process – a case study Ernst Kleynhans Industrial Science Dissertation submitted in partial fulfilment of the requirements for the degree Master of ...

2015/05/20· Replacement of bentonite in hematite ore pelletisation using a combination of sodium lignosulphonate and copper smelting slag. Ironmaking Steelmaking: Vol. 43, No. 3, pp. 203213. doi: / | ...

WhatsApp)

WhatsApp)