WhatsApp)

WhatsApp)

Raw material grinding is one of the processes used to manufacture cement of highest quality.

Material ground consists of limestone, cement rock, ... know how unquestionably qualify Grate Discharge grinding for the Cement Industry. RAW CEMENT GRINDING.

CEMENT INDUSTRY Output of a Seminar ... A cement production plant consists of the following three processes. 1. ... Figure 4 Dry process raw material grinding system5

An online course designed to take students through the complete cycle of raw material grinding and preparation, clinker grinding, milling and separation cycles.

The Advantages of Wet Process Use in Cement Industry | Grinding raw materials to create cement can be ... are: ... For the cement raw material grinding ...

3 Cement Download as PDF ... Product/ technology Function Heat recovery Raw material grinding Rotary kiln exhaust heat recovery Cement calcinations Coal ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

According to statistics, over 60% cement plant power will be consumed to grind materials in dry process cement production line. Among which, over 30% is used for raw ...

Volume 3, Issue 5, November 2013 ... raw material handling Grinding, ... preheaterkiln cooler, clinker grinding (cement mill), ...

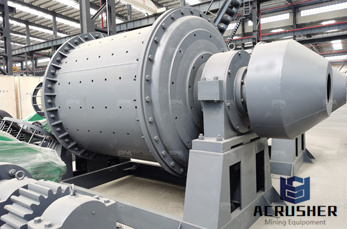

Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the ...

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

Grinding trends in the cement industry Cement Lime Gypsum. 10 Combination grinding system with roller press. ... 23 Raw material mill .

cement (building material) Encyclopedia Britannica . cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in ...

8 YRS Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd. China (Mainland) | Manufacturer, Trading Company. Supplier Assessments:

raw material grinding cement industry – CGM Mine Machine . Ball grinding mill, roller grinding mill for slag, coal, fly . Alternative raw materials (ARM) like ...

History. The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture ...

JK Cement Ltd of India has contracted ThyssenKrupp Polysius to supply three new grinding plants equipped with POLYCOM highpressure grinding rolls. The...

The primary aim of Mathematical Problems in Engineering is rapid publication ... a continuous ball mill is studied for optimizing cement raw material grinding ...

Cement Facts: History of Cement: ... Raw Materials Proportioning Grinding. ... has to be treated as an individual raw material component and the appropriate ...

Raw material preparation. From the quarry to raw meal feeding ... the raw material needed for the cement production ... of the raw material grinding

How cement is made and history of ... The first step is to quarry the principal raw materials, mainly ... The finely ground raw material or the slurry is fed into ...

raw material grinding cement. ... SAM screen can separate the stuff of different size The most important raw materials for making cement are limestone,

Why Cement Raw Material Grinding is Important News Date: 15:53:33. Proper analysis and identification of raw materials are essential to achieving the best ...

Raw Material Cement, Wholesale Various High Quality Raw Material Cement Products from Global Raw Material Cement Suppliers and Raw Material Cement Factory,Importer ...

WhatsApp)

WhatsApp)