WhatsApp)

WhatsApp)

Overview Sponge iron is formed through the reduction of iron ore to metallic iron through reaction with carbon in the form of coal, etc at approx 1100 degree Celsius. Sponge iron is also referred to as direct reduced iron, metalized ...

Tata Sponge production surges 8 per cent to record lakh tonne in 201617 Based on the experience gained from using imported coal of superior quality having a positive impact on the quality of sponge iron, the company sourced ...

Read more about Sponge iron prices fall on cheaper raw materials on Business Standard. Mumbai, 25 OctoberSponge iron prices have fallen five per cent so far this month, owing to a steep fall in the cost of production. This follows a ...

Directreduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) to iron by a reducing gas or elementary carbon produced from natural gas or coal. Many ores ...

mail: ak_poonia) Anil K. Poonia and Shabina Khanam, Member, IACSIT Simulation of Rotary Kiln Used in Sponge Iron Process Using ANN IACSIT International Journal of Engineering and Technology, Vol. 6, No. 2 ...

Input Cost Notes Raw Material Cost Info rmation Sources Thermal coal, iron ore and natural gas data reproduced with thanks and permission from the International Monetary Fund. Electricity figures are provided with thanks from the ...

Sponge Iron MSP Sponge Iron plant uses the highest grade of iron ore and premium quality coal. This ensures very high metallization of Sponge Iron. Sponge Iron is fast becoming a significant input in lowcost steel production. With ...

Get latest news, prices, tenders, statistics and market report on steel, iron ore, coal, scrap, billet, hrc, crc, rebars, Ferro alloys and coke. Email: info Helpdesk : +91 97700 56666 Go Subscription Free Trial ...

Contents • India – Steel Production and Iron ore scenario • Why Utilization of Iron ore fines • Essar''s contribution in utilization of iron ore fines slimes • Benefciiation • Agglomeration • Slurry pipeline transport • Essar''s BF operation ...

growth was entirely due to higher Chinese imports. For the past decade, iron ore and coal have each accounted for over 30% of the total dry bulk trade. l Corporate Concentration Corporate concentration in the iron ore industry l l l ...

07Jul2017 | 17:39 » Iron Ore Prices At Qingdao Port, China 07Jul2017 | 17:38 » Rebar, Coil and Special Steel Price in Shanghai,China 07Jul2017 | 17 ...

Sponge iron is a metallic product produced through direct reduction of iron ore in the solid state. It is a substitute for scrap and is mainly used in making steel through the secondary route. The process of sponge iron making aims to ...

Direct Reduced Iron (DRI) Description / Application / Shipment Storage / Risk factors Directreduced iron (DRI), also called sponge iron, is produced from direct reduction of iron ore (in the form of lumps, pellets or fines) by a ...

Coal in the sponge industry Sponge iron is iron reduced directly in solid state using coal gas, natural gas or coal as reductants and is also known as Directly Reduced Iron (DRI). India entered the sponge iron industry only in 1980.

REDUCTION AND SWELLING OF FIRED HEMATITE IRON ORE PELLETS BY NONCOKING COAL FINES FOR APPLICATION IN SPONGE IRONMAKING Mithilesh Kumar, Himanshu Baghel, and Saroj Kumar Patel Department of ...

Tata Sponge Iron (TSIL) was incorporated in 1982 as joint venture between Tata Steel and the Industrial Promotion and Investment Corporation of Orissa (IPICOL). Later in 1991, Tata Steel acquired IPICOL''s stake in joint venture.

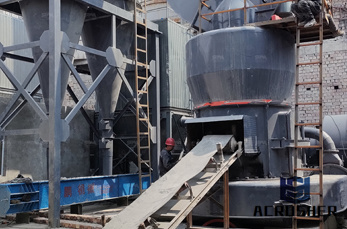

Sponge Iron Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And ...

2007/03/18· Sponge Iron Report Multi Commodity Exchange of India Ltd 102 A, Landmark, Suren Road, Chakala, Andheri (East), Mumbai 400 093 Tel: 022 ... Pittsburg Midway Coal Mining Co. v. Shepherd ...

1 RAW MATERIAL General The major Raw Materials required for production of Sponge Iron by the rotary kiln process are: sized graded Iron Ore and NonCoking coal. Limestone, in small quantities, is also ...

The iron and steel industry is one of the most important industries in India. During 2014 through 2015, India was the third largest producer of raw steel and the largest producer of sponge iron in the world. The industry produced ...

Rotary Kiln Process of Making Sponge Iron// 13 that the entire production by number 2, 3 and 4 countries is through gas based route while in India, more than half the production is by the coal based route. THE INDIAN SCENE

Direct Reduced Iron (DRI) Overview Directreduced iron (DRI), also called sponge iron,[1] is produced from direct reduction of iron ore (in the form of lumps, pellets or fines) by a reducing gas produced from natural gas or coal. The ...

1. Metal Bulletin Indices Introduction 2. Iron Ore Spot Market Update 3. InterGrade Price Trends 4. DirectReduction Pricing 5. DRGrade Pellet Premium Assessment ... Objective and mathematical calculations Robust ...

2013/08/02· India, the world''s largest producer of direct reduced iron, or DRI, is battling illegal imports of Iranianorigin sponge iron, industry sources said Friday. About 500,000 mt of gasbased DRI were illegally imported during fiscal ...

WhatsApp)

WhatsApp)