WhatsApp)

WhatsApp)

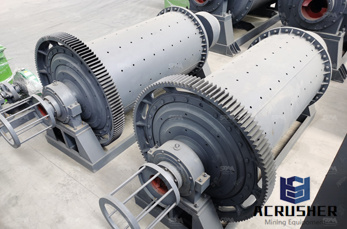

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Introduction. A high speed spindle that will be used in a metal cutting machine tool must be designed to provide the required performance features.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Schaeffler Group Industrial 1 Contents Product Description 2 Ball Nuts 3 Load Rating And Life 4 Critical Speed And Buckling Load 5 Ordering Designations 6

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

About Gulin. Looking for Information about Gulin? Visit for company news and careers as well as information about Gulin''s entire portfolio ...

Sep 09, 2013· Home Inspection Services in Chicago area. Call us at for a free quote and have a home inspector stop by your future property. The Inspection ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Excel speed/feed calculators for Ball Nose Finishers, 90Degree Square Shoulder Mills and Toroid Cutters. Common formulas to help calculate RPM, SFM, IPM, IPT and MRR ...

The VM1040E vertical mill machine comes with tons of standard features making it fit right in the Baileigh Industrial line up. Shop for your vertical mill today!

Running the correct PROMAX solid carbide end mills at the proper speeds and feeds is critical to obtaining the best production times and tool life.

Our free speed and feed calculator can be used to determine the spindle speed (RPM) and feed rate (IPM) for the specified cutting conditions, as well as the cut time ...

Register. In order to login you must be registered. Registering takes only a few moments but gives you increased capabilities. The board administrator may also grant ...

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

I have often looked at my red pillar drill and thought "that should make a good mill". I''m not the first to convert a cheap drill into a homemade mill but if you ...

How to Calculate Macros For Fat Loss (Cutting) That Are Maximally Simple and Flexible. March 24, 2016 6 Comments

114 Note: All speed and feed data are suggested starting points. They may be increased or decreased depending on machine condition, hole depth, finish required ...

Even my mill was converted to metric units it was still a lot of work to calculate table travel to "turns on knobs". Metric version is quite d as one turn on the ...

Based in Milwaukee, WI – CGC Tools has over 30 years experience manufacturing the best carbide drills, end mills and cutting tools in the industry.

Ball Screws: Ball Screws Select from the dropdown menus below (in any order) to determine the appropriate Ball Screw model. SPEC 1 DIAMETER: Select .375 .500

Ball bearing part number selection can only be properly performed with a working knowledge of ball bearing performance expectations and requirements. Size ...

Chiploads, Surface Speed and Other Concepts. CNC Milling Feeds and Speeds Cookbook

Guhring understands that several manufacturers new to thread milling may need help programming their CNC machines properly.

Once you''ve got the mill trammed, your next step is very likely going to be putting a vise onto the table. Here''s how various folks on the web have reported ...

WhatsApp)

WhatsApp)